How to Build a Circular Business Model

Linear “take-make-waste” systems do not function in the current world anymore. Waste generation will increase 70% in the world by 2050, putting intense pressure on the economy, the planet, and society.

Businesses are at the focal point of this change because they have the power to create solutions as well as be part of the issue.

A central response is understanding how to build a circular business model so that companies can close the loop totally using the latest technologies like SynPet’s Thermal Conversion Process (TCP), which goes beyond incremental improvement. Zero-waste is a business strategy that is not limited to the sustainability goals.

Companies can close the loop completely with the latest technologies like SynPet’s Thermal Conversion Process (TCP), which goes beyond incremental improvement.

What is a Circular Business Model?

A circular business model is a fundamental rethink of how we go about value creation, and not a perpetual fad for sustainability. The circular approach closes the loop, as compared to the conventional linear model that operates on a “take–make–waste” basis.

Circularity attempts to leave resources in service for as long as necessary, recycling them when each cycle ends, rather than extracting raw materials, manufacturing, and then discarding them at the end of useful life.

At the heart of every circular business model are five principles.

- Reduce: By being more intelligent in terms of design and optimizing waste management, use fewer resources and create less waste.

- Reuse: By designing items so they are reused multiple times, you can keep them in service longer.

- Recycle: After use, gather valuable materials and feed them into the manufacturing process. This is where SynPet’s technology comes into its own because it includes previously unrecyclable plastic and waste streams within the recycling process.

- Redesign: Break free from small tweaks to deeply rethink systems.

- Regenerate: Go beyond efficiency to actively restore and renew natural systems.

Having a circular business model benefits both the economy and the environment. It is not just about sustainability but creating more savvy, resilient businesses.

The Urgency Behind Going Circular: Why Now?

Why does a circular business model matter so much today? The answer is simple: the world around us has changed, and businesses can’t afford to operate as if it hasn’t.

Global Pressures Are Mounting

Governments are tightening sustainability regulations, investors are embedding ESG performance into decisions, and consumers are voting with their wallets. A business model for a circular economy speaks directly to these demands by cutting emissions, reducing waste, and demonstrating accountability.

The Economics Are Undeniable

Circularity drives efficiency. By reusing resources, companies spend less on virgin inputs and reduce disposal costs. What once looked like “extra effort” is now a proven way to protect margins and secure long-term profitability.

Reputation Is Everything

Businesses embracing circular models are credited. They differentiate themselves in busy markets, win over green consumers, and build confidence with partners and investors. For most, going for a zero-waste business model is about survival.

Take action toward circularity!

The shift to a circular business model can feel complex, but we can help. SynPet’s TC technology makes it possible to handle even the most difficult waste streams and turn them into resources for your supply chain.

Explore how we can support your company’s transition to circular practices.

Step-by-Step Guide to Building a Circular Business Model

When the transition to a circular business model is divided into manageable, straightforward steps, it is far simpler. Here are some steps businesses may take:

Step 1: Evaluate Present Activities

- Recognize your current biggest effects before revamping. Perform a sustainability audit by mapping energy use, waste production, and material use to establish baselines.

- Find inefficiencies and waste points. Determine where resources, such as extra packaging or production scrap, are escaping the system.

Step 2: Redesign Products & Processes

- Apply circular design principles – Prioritize durability, repairability, and recyclability from the start.

- Use material substitution – Replace virgin resources with recycled or renewable inputs like SynPet’s Circular Naphtha.

- Adopt modular design for longevity – Create products and processes with interchangeable parts to extend lifespan and reduce waste.

Step 3: Engage Suppliers & Partners

- Collaborate with suppliers for recycled or reusable materials – Ensure inputs align with your zero-waste business vision.

- Build closed-loop supply chains – Work with partners on return systems, packaging reuse, and material take-back programs.

- Align on shared goals – Set joint KPIs and incentives so every link in the chain supports your sustainable business strategies.

Step 4: Implement Circular Practices

- Integrate recycling and reuse – Reintroduce materials into production instead of discarding them.

- Refurbish products – Repair and renew items to extend their life and create new revenue streams.

- Rethink logistics, packaging, and production – Reduce transport emissions, switch to reusable packaging, and cut inefficiencies.

Step 5: Measure & Optimize

- Track KPIs – Measure waste reduction, cost savings, and carbon footprint improvements.

- Report and share progress – Build credibility with transparent sustainability reporting.

- Iterate for improvement – Use data insights to refine processes and adopt innovations like SynPet’s TCP to scale your business model for circular economy.

How SynPet Supports Circular Transformation

Even the best sustainability strategies can stall without the right technology. This is where SynPet makes the difference — enabling companies to turn even “non-recyclable” waste into new resources.

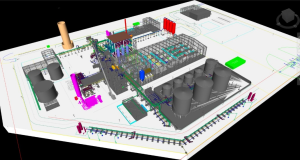

- Plastic recycling technology – SynPet’s Thermal Conversion Process (TCP) converts all carbon-based waste — from plastics and packaging to hazardous residues — into valuable outputs like Circular Naphtha, renewable crude oil, natural gas, liquid fertilizer, and biochar.

- Case examples – A packaging producer could replace virgin fossil feedstock with Circular Naphtha to create fully recyclable plastic products. An industrial manufacturer could cut landfill waste by using SynPet’s TCP to process mixed or contaminated waste streams.

- Integration tips – SynPet solutions can be embedded in product design and supply chains: sourcing recycled feedstock, reducing dependence on fossil fuels, and supporting a zero-waste business strategy without costly pre-treatment or sorting.

By partnering with SynPet, companies not only strengthen their sustainable business strategies, but they also unlock new economic value from materials once considered useless.

Circular Business Model in Action: Real-World Examples

Circularity is no longer just a theory — leading companies are already proving its value in practice.

- IKEA – Committed to becoming fully circular by 2030, with 100% of products made from renewable or recycled materials. This shows how a business model for circular economy can scale in retail.

- Patagonia – Built its reputation around repair, reuse, and resale programs that extend product lifecycles and reduce waste. A clear example of a zero-waste business mindset driving brand loyalty.

- Unilever – Rolling out refillable and recyclable packaging across global brands, saving costs while meeting consumer expectations for sustainable choices.

With technologies like SynPet, the possibilities expand even further: what was once considered impossible to recycle can now become the foundation of truly sustainable business strategies.

Let’s build your circular future together!

The age of “take–make–waste” is coming to an end.

Businesses that want to stay relevant and resilient need to reimagine how value is created.

Create new value, new opportunities, and a truly zero-waste business with us.