What Is Plastic Circularity and Why Does It Matter

Every year, the world produces over 400 million tonnes of plastic, and less than 10% is effectively recycled.

The rest ends up in landfills, incinerators, or worse, our oceans. While conventional recycling has helped slow the flow of waste, it’s far from solving the crisis. Most plastics degrade in quality after each recycling loop, eventually becoming unrecyclable and destined for disposal.

This is where the concept of plastic circularity comes in — not just as a solution, but as a transformative shift in how we produce, use, and recover plastics. In this blog post, we’ll delve into the details of plastic circularity.

What Is Plastic Circularity?

Plastic circularity is a forward-thinking design and production approach that aims to keep plastics in use for as long as possible, reducing the need for new (virgin) materials and extending the life of existing ones.

Instead of treating plastic as a disposable commodity, this model views it as a valuable resource that can be recovered, regenerated, and continuously reintroduced into the economy.

To understand its significance, it’s useful to compare it with the traditional linear economy — the “take-make-dispose” model. In that system, raw materials are extracted, turned into products, consumed, and then discarded, often ending up in landfills or polluting the natural environment.

When applied to plastics, this linear approach has led to a massive accumulation of waste, persistent environmental damage, and heavy reliance on fossil fuel resources.

How Plastic Circularity Works

Plastic circularity isn’t a single technology or method — it’s an integrated system of strategies designed to keep plastics in circulation for as long as possible, minimizing waste and resource extraction.

An advanced plastic circularity model often combines the following approaches:

1. Reduction

The most effective way to tackle plastic waste is to prevent it from being created in the first place. Reduction strategies focus on:

- Smarter product design that minimizes material use without compromising performance

- Material substitution with renewable or compostable alternatives where appropriate

- Lightweighting of packaging to cut raw material use and transportation emissions

- Eliminating unnecessary single-use plastics through redesign and regulation

By cutting the demand for virgin plastic, the reduction directly lowers pressure on fossil fuel resources and reduces production-related emissions.

2. Reuse

Instead of discarding plastics after one use, reuse systems extend product lifespans through:

- Refill and return schemes for consumer goods like water bottles, cleaning products, and cosmetics

- Reverse logistics programs, where manufacturers collect and refurbish their own products

- Component repurposing in industrial and manufacturing settings

- Adoption of modular product design, making it easier to repair or replace individual parts rather than the whole item

These models keep products in circulation longer, reducing the overall volume of plastic waste entering the system.

3. Mechanical Recycling

Mechanical recycling is one of the most common plastic recycling methods. This process involves:

- Collection and sorting of post-consumer or post-industrial plastics

- Cleaning and shredding into flakes or pellets

- Melting and remolding into new products

While effective for certain clean, single-type plastics (e.g., PET bottles, HDPE containers), mechanical recycling has limitations:

- Quality degrades after repeated cycles (“downcycling”)

- Cannot efficiently process multi-layer, contaminated, or mixed plastics

- Requires high-quality feedstock to produce high-quality output

4. Advanced Recycling

Advanced (or chemical) recycling technologies go beyond mechanical methods by breaking plastics down into their basic chemical building blocks or fuels. Techniques include:

- Thermal conversion (heat-based processes without oxygen, like SynPet’s TCP)

- Chemical depolymerization (breaking polymers into monomers for re-polymerization)

- Gasification and pyrolysis (producing syngas or oil from waste plastics)

This approach can handle contaminated, multi-layer, and composite plastics — streams that mechanical recycling can’t manage — while maintaining material quality through multiple cycles.

At the core of all these strategies is a closed-loop system, where products are designed for longevity, collection systems capture used materials, and recycling technologies reintroduce these materials into production.

This loop ensures that plastics in packaging, textiles, automotive components, consumer goods, and more can be regenerated rather than discarded.

Benefits of Plastic Circularity

Plastic circularity delivers a powerful combination of environmental, economic, and business advantages, making it a strategic priority for organizations committed to sustainability.

From an environmental perspective, circular systems significantly reduce plastic waste by diverting large volumes from landfills, incinerators, and natural habitats.

This helps prevent pollution, protecting biodiversity and reducing microplastic contamination in oceans and soil.

Moreover, by decreasing reliance on virgin plastic production — an energy-intensive process — circularity lowers greenhouse gas emissions and contributes to climate change mitigation.

The economic benefits are equally compelling. Circular practices improve resource efficiency by maximizing the value extracted from each unit of plastic throughout its lifecycle. Producing recycled plastics generally consumes less energy than manufacturing virgin materials, resulting in cost savings and lower carbon footprints.

Additionally, reducing dependence on virgin feedstocks helps insulate businesses from volatile oil and gas prices, strengthening long-term market resilience.

From a business standpoint, embracing plastic circularity supports ESG compliance and demonstrates measurable progress toward sustainability and net-zero targets.

It also positions companies to stay ahead of tightening waste and recycling regulations worldwide.

Beyond compliance, leading in sustainable practices enhances brand reputation, fostering customer loyalty and attracting sustainability-focused investors.

How SynPet Enables True Plastic Circularity

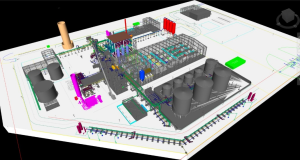

SynPet’s Thermal Conversion Process (TCP) is a breakthrough in advanced recycling, offering a practical and scalable solution for plastics that are traditionally considered unrecyclable.

Unlike conventional methods, TCP can process mixed, contaminated, and hard-to-recycle plastics — materials that would otherwise end up in landfills — without the need for extensive sorting or pre-treatment.

The process transforms these challenging waste streams into high-purity fuels and feedstocks, which can be seamlessly reintroduced into industrial supply chains, supporting true circularity.

The environmental impact is significant. By diverting substantial amounts of plastic waste from disposal and replacing virgin plastic production with recycled outputs, TCP helps reduce lifecycle carbon emissions.

It also decreases dependence on fossil fuels, amplifying its role in combating climate change.

From an economic and business perspective, TCP enables manufacturers to integrate genuine closed-loop systems into their operations, ensuring that materials are continually repurposed rather than discarded.

This not only strengthens ESG performance and regulatory readiness but also allows companies to meet sustainability goals without compromising on product quality or operational efficiency.

Ready to explore what true plastic circularity could look like for your business? We can showcase how our advanced TCP technology is turning waste into value. Contact SynPet today |