The transition toward a circular economy where materials are reused, recovered, and continually cycled has become a defining priority for industries worldwide. Nowhere is this shift more urgent than in the petrochemical sector, where reliance on virgin fossil-based feedstocks continues to create economic exposure, supply-chain vulnerability, and environmental pressure.

As demand grows for sustainable, lower-emission alternatives, circular naphtha substitutes (CNS™) are emerging as one of the most promising pathways toward a more resilient and climate-aligned petrochemical value chain.

Why Circular Naphtha Substitute Matters Today

Refining and petrochemical companies face a complex landscape:

Volatile feedstock prices tied to crude oil markets

Increasing environmental regulations across Europe and beyond

Shift toward non-fossil mobility systems, reducing long-term demand for conventional fuels

Growing pressure to reduce Scope 1–3 emissions along the plastics lifecycle

At the same time, plastic waste continues to accumulate globally, placing pressure on governments and industries to accelerate advanced recycling solutions.

Circular naphtha substitute offers a strategic bridge between these two realities.

By converting waste-derived hydrocarbons into refinery-compatible feedstock, CNS™ supports both decarbonisation and circularity, enabling petrochemical operations to access a more stable, sustainable source of molecules.

How Circular Naphtha Substitute Fits Into the Circular Economy

Circular naphtha substitute is designed to integrate seamlessly with existing petrochemical processes, particularly steam cracking. Unlike fossil-based naphtha, which relies on extraction of finite resources, CNS™ is derived from end-of-life materials, helping close the loop on plastic and other carbon-containing waste.

Key advantages within the circular model:

Reduces dependence on virgin fossil feedstocks

Creates value from materials that would otherwise be landfilled or incinerated

Supports decarbonisation by enabling lower-emission pathways for petrochemical production

Provides a scalable, drop-in molecule compatible with existing infrastructure

As Europe advances its climate and circularity goals, the ability to produce naphtha-range products from waste streams has become a defining enabler of next-generation petrochemical strategy.

How Circular Naphtha Substitute Strengthens Petrochemical Competitiveness

Circular naphtha substitute offers several strategic benefits for the industry:

1. Enhances Feedstock Security

CNS™ reduces exposure to crude-oil-driven price fluctuations, creating a more stable and predictable procurement environment.

2. Supports Climate and Sustainability Targets

Using circular feedstocks helps companies progress toward net-zero commitments, Scope 3 reductions, and regulatory compliance under frameworks such as the EU Green Deal.

3. Unlocks New Value from Waste

By transforming waste materials into high-quality feedstock, CNS™ contributes to a more efficient, resource-conserving industrial ecosystem.

4. Strengthens Supply-Chain Resilience

Domestic or regional production of circular feedstocks reduces reliance on long-distance fossil supply chains.

5. Drives Innovation

Circular molecules open pathways to new product families, including bio-based or low-carbon chemicals, that support emerging consumer and regulatory expectations.

Industrial Applications of Circular Naphtha Substitute

Circular naphtha substitutes can be used across a spectrum of petrochemical and chemical use cases, including:

| Application | Description | Strategic Impact |

|---|---|---|

| Chemical Recycling Loops | Enables circular processing of plastics into molecular feedstock | Reduces plastic waste and supports circularity targets |

| Steam Cracking Feedstock | Delivers naphtha-range components suitable for cracking | Supports production of olefins and aromatics with lower-emission input streams |

| Cleaner Fuels & Bio-Derived Blends | Enables blending opportunities for advanced fuels | Lowers lifecycle emissions in mobility applications |

| Sustainable Chemicals | Offers a platform for producing low-carbon or bio-aligned chemicals | Reduces reliance on petroleum-based feedstocks |

| Efficiency Improvements | Provides consistent molecular quality that optimises operations | Supports lower energy consumption and operational stability |

This versatility makes CNS™ a pivotal resource for companies seeking to diversify, decarbonise, and future-proof their product portfolios.

Where SynPet Fits In: Advancing Circularity Through TCP® Technology

SynPet’s patented Thermal Conversion Process (TCP®) represents more than a decade of R&D and industrial evolution. Unlike conventional methods, TCP®:

Processes all types of carbon-containing waste, including hard-to-recycle plastics

Requires no pre-treatment such as cleaning, drying, or sorting

Uses water under controlled conditions as a key reagent

Delivers a consistent circular naphtha substitute suitable for direct blending into steam cracker feedstock

These capabilities position TCP® as a reliable platform for large-scale circular feedstock production.

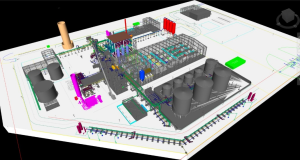

SynPet validated its technology at its R&D facility in Istanbul and is now scaling to commercial operation with its flagship investment: the €300M Circular Recycling Hub at the Port of Antwerp-Bruges.

This facility will convert mixed and untreated plastic waste into high-quality circular naphtha substitute and renewable natural gas, supporting Europe’s transition toward a circular and low-carbon petrochemical ecosystem.

A Simplified Look at TCP®’s Multi-Stage Transformation

While the technology is proprietary, the overarching stages include:

Depolymerisation: Breaking down organic and inorganic structures using water under controlled heat and pressure

Hydrolysis & Molecular Reformation: Separating carbon-based molecules from contaminants and reshaping them into longer hydrocarbon structures

Thermal Cracking: Refining these hydrocarbons into naphtha-range fractions suitable for petrochemical use

The result is a circular feedstock that aligns with petrochemical specifications without relying on fossil extraction.

Conclusion: Circular Naphtha Substitute is Reshaping Petrochemical Strategy

As the petrochemical industry continues its transformation, circular naphtha substitutes offer a high-impact opportunity to:

Reduce reliance on fossil feedstocks

Lower lifecycle emissions

Strengthen energy and material security

Create economic value from waste streams

Support regulatory alignment and sustainability commitments

With TCP® technology and its state-of-the-art Circular Recycling Hub in Antwerp, SynPet is helping accelerate the shift toward a circular, resource-efficient, low-carbon petrochemical future.