Transitioning the Plastic Industry to a Circular Economy

Plastic is an integral part of modern life—lightweight, durable, and versatile. Yet, its convenience comes at a high environmental cost. The traditional “take, make, dispose” approach has led to a global plastic pollution crisis.

Plastic production has sharply increased over the last 70 years. In 1950, the world produced just two million tonnes; today, we produce over 450 million tonnes annually.

To address this, the plastic industry is undergoing a much-needed shift toward circular economy principles, where materials are reused, recycled, and regenerated.

This transition isn’t just an environmental necessity—it’s a business imperative that demands plastic innovation, global collaboration, and systemic change.

This blog post explores how the plastic industry is evolving toward a circular economy model, highlighting new recycling technologies and strategies for redesigning plastic products for sustainability.

What Is a Circular Economy in the Context of the Plastics Industry?

The linear model of plastic production and use follows a one-way path: raw materials are extracted, products are manufactured, used, and then discarded. This unsustainable system has resulted in increasing amounts of plastic waste, much of which ends up in landfills or pollutes the environment.

By contrast, a circular economy for plastics seeks to eliminate waste and pollution by keeping materials in use for as long as possible. Unlike the linear model, the circular approach emphasizes durability, repairability, recyclability, and resource efficiency.

The model encourages collaboration between businesses and consumers to minimize waste through practices like reusing, repairing, refurbishing, and recycling. It stands in stark contrast to the linear system by promoting more sustainable use of materials.

In practical terms, a circular economy for plastics involves:

- Maximizing the lifespan of materials and products

- Recapturing materials once they reach the end of their life cycle

- Transforming recovered resources into new items

- And, where possible, repeating this cycle continuously

This transition supports both environmental sustainability and economic resilience, helping industries prepare for resource scarcity and evolving regulations.

How to Achieve Plastic Circularity

The ultimate aim of the circular model is to extend resource lifespans, reduce waste, and minimize environmental impact. Key strategies include:

- Reducing reliance on virgin resources: By streamlining production and designing for durability, companies can significantly cut the need for raw material extraction.

- Promoting reuse: Extending the life of products through reuse helps delay disposal and lowers demand for new materials.

- Recycling materials into new products: Instead of sending used plastics to landfills, circular systems focus on collecting and processing them to keep materials in circulation.

- Recovering energy as a last resort: When recycling isn’t feasible, waste can be used to recover energy, but this should be considered only a fallback option.

Key Challenges of Plastic Circularity

Shifting the plastics industry to a circular model involves overcoming a range of systemic and practical challenges:

- Inadequate Recycling Infrastructure: Many countries, especially developing ones, lack efficient systems for collecting and processing plastic waste. Poor handling often leads to contamination, reducing the recyclability and value of materials. Without adequate sorting and collection networks, valuable plastics are lost to landfills or the environment.

- High Costs of Recycled Materials: Recycled plastics are often more expensive than virgin alternatives. The advancement of recycling technology requires significant capital investment, and fluctuating oil prices can make virgin plastic more economically attractive, discouraging businesses from adopting recycled materials.

- Declining Material Quality: With each recycling cycle, plastics tend to degrade in quality, limiting their use in high-performance applications like medical devices and food packaging. Achieving consistent quality standards for recycled materials remains a major technical hurdle.

- Consumer Habits and Low Awareness: A lack of public awareness around proper recycling practices contributes to material contamination and inefficient recovery. Additionally, many consumers continue to prioritize convenience, opting for single-use plastics over reusable options.

- Fragmented Regulations and Lack of Global Standards: Varying recycling regulations across countries create barriers to scalable plastic waste management systems. This lack of global standardization complicates efforts by companies to design sustainable packaging that meets international requirements.

- Complex Packaging and Mixed Plastics: Multilayered and mixed-material plastics—common in food packaging—are particularly difficult to recycle. The advanced technologies required to separate different polymer types are not yet widely available or affordable.

Technologies Driving the Circular Transition

Technological innovation is a cornerstone of advancing plastic circularity. Key developments include:

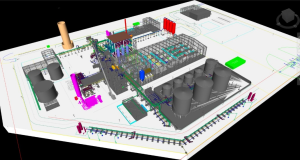

- Chemical and Advanced Recycling Technologies: Unlike mechanical recycling, chemical recycling breaks plastics down to their molecular building blocks, allowing for higher-quality and potentially infinite recyclability. Techniques like pyrolysis, solvolysis, and thermal conversion—including SynPet’s TCP process—are unlocking new value from previously unrecyclable plastic waste.

- AI and Robotics in Waste Sorting: Artificial intelligence and robotics are improving the speed and accuracy of waste sorting, reducing contamination and increasing recovery rates. These technologies help streamline material separation, making recycling more efficient.

- Digital Tracking and Circular Supply Chains: Tools like digital product passports and blockchain enable transparency and traceability throughout the supply chain, making it easier to manage materials in circular loops.

Alternative Materials and Design Innovations

Design plays a pivotal role in making plastics more circular. Key innovations include:

- Bioplastics and Compostables: Although promising, bioplastics face challenges in terms of scalability, infrastructure compatibility, and environmental trade-offs. Their effectiveness in a circular system depends on proper end-of-life handling and composting infrastructure.

- Design for Recycling: Designing products and packaging with mono-materials, removable labels, and minimal colorants improves recyclability. Initiatives like the Ellen MacArthur Foundation’s Global Commitment are accelerating industry adoption of these principles.

- Extended Producer Responsibility (EPR): EPR policies make manufacturers responsible for their products’ end-of-life, incentivizing sustainable design, better collection systems, and reuse models.

Why Circularity Benefits Everyone

The benefits of adopting a circular economy for plastics extend across environmental, economic, and social dimensions:

- Environmental: Reduces plastic pollution, limits the use of fossil resources, and cuts greenhouse gas emissions

- Economic: Creates new business opportunities, lowers dependence on virgin materials, and fosters innovation

- Social: Improves public health, generates green jobs, and supports progress toward the Sustainable Development Goals (SDGs)

Industries that rely heavily on plastics—such as packaging, construction, and automotive—stand to gain long-term resilience by embracing circular practices.

The Road Ahead: What’s Needed Next?

To fully achieve plastic circularity, the following steps are essential:

- Stronger Policy Frameworks: There needs to be alignment on global recycling standards, extended producer responsibility (EPR) legislation, and incentives for sustainable materials.

- Cross-Sector Collaboration: Manufacturers, recyclers, and innovators, such as SynPet, must work together to scale and standardize circular solutions.

- Consumer Engagement: Public education and behavioral changes are critical to encourage participation in reuse and recycling systems.

Although the path to full circularity is complex, technology, collaboration, and innovation will be key drivers of progress in the future of the plastic industry in a circular economy.

The plastic industry is at a turning point. Staying on a linear path threatens ecosystems, human health, and economic stability. However, transitioning to a circular economy presents a clear alternative—one that redefines how plastic is produced, used, and valued.

At SynPet, we believe that advanced recycling technologies are essential for this transition. Our Thermal Conversion Process (TCP) is designed to close the loop by converting plastic waste into high-value resources, helping to drive the industry toward a sustainable, circular future.