The world is facing a growing environmental challenge in the form of plastic waste. Plastic materials have become deeply embedded in modern life, yet their end-of-life management continues to place pressure on natural systems, ecosystems, and supply chains.

To address this challenge, the concept of a circular economy in plastic recycling has gained increasing attention. Rather than relying on linear “take–make–dispose” models, a circular economy focuses on keeping materials in use for as long as possible, extracting maximum value from them, and minimising waste and emissions.

This article explores what a circular economy means in the context of plastic recycling, why it matters, and how emerging recycling approaches can support more sustainable material cycles.

Understanding a Circular Economy

A circular economy is an economic model designed to reduce waste and make more efficient use of resources. In a circular system, materials are reused, recovered, and reintroduced into the value chain, rather than being discarded after a single use.

This approach contrasts with traditional linear models, which depend heavily on continuous extraction of virgin resources and generate large volumes of waste.

The core principles of a circular economy include:

Designing out waste and pollution

Keeping products and materials in use for as long as possible

Supporting the regeneration of natural systems

Applied to plastics, these principles aim to reduce dependence on fossil-based inputs while improving material efficiency across the lifecycle.

Why the Circular Economy Matters

Implementing circular economy principles is increasingly seen as essential for long-term sustainability and resilience. A more circular approach can help:

Reduce waste generation and environmental leakage

Improve resource efficiency and material security

Lower emissions associated with extraction and disposal

Support innovation and new economic activity

By reducing reliance on finite resources, circular systems also contribute to more stable and resilient industrial supply chains. For plastics in particular, circularity offers a pathway to balance the material’s functional benefits with environmental responsibility.

Circular Economy in Practice

The circular economy envisions a world where resources are utilised more efficiently and sustainably, with the aim of reducing waste and extending material lifecycles. This concept integrates principles of sustainability and efficiency into economic systems and is already being applied by cities and corporations across different sectors.

This shift toward circular models is widely seen as a way to improve long-term resilience by reducing dependency on finite resources and improving material recovery. Examples of circular economy practices include:

- Carpet Recycling UK, which focuses on collecting and recycling waste carpets into new products such as carpet underlay and equestrian surfaces. By capturing and reusing carpet waste, the organisation helps reduce the environmental impact of a material that is often landfilled.

- H&M’s Garment Collecting Program, which applies a closed-loop approach in the fashion industry by collecting used clothing for reuse, recycling into new products, or energy recovery, helping reduce textile waste.

- Apple’s recycling initiatives, which aim to recover materials from end-of-life devices and reintroduce them into manufacturing processes, supporting the development of more circular supply chains for consumer electronics.

These examples illustrate how circular economy principles can be implemented within existing industries, supporting waste reduction while maintaining material value.

The Plastic Waste Challenge

Plastic waste remains a global environmental issue with implications for ecosystems, human health, and resource management. The continued production of single-use plastics, combined with limitations in existing recycling systems, has contributed to the accumulation of plastic waste worldwide.

Each year, large volumes of plastic waste are generated and either landfilled, incinerated, or released into natural environments. These pathways can contribute to environmental pollution, harm wildlife, and result in greenhouse gas emissions associated with disposal processes.

According to widely cited global data, plastic production increased from approximately 2 million tonnes in 1950 to around 460 million tons in 2019. At the same time, estimates suggest that only a relatively small share of plastic waste is recycled through conventional methods, and that most plastics are not recycled multiple times.

In addition, a significant proportion of disposable plastic products are derived from virgin fossil-based feedstocks. The production, use, and disposal of these materials are expected to remain a material contributor to global emissions without further improvements in circularity and waste management.

These trends highlight the importance of advancing circular economy approaches for plastics, with a focus on reducing waste generation, improving recycling outcomes, and lowering dependence on fossil-based resources.

How a Circular Economy Can Transform Plastic Recycling

A circular economy approach has the potential to reshape plastic recycling by moving beyond material recovery alone. In a circular system, plastics are treated as ongoing resources rather than disposable products.

Plastics offer valuable properties such as durability, lightweight performance, and cost efficiency, which is why they are widely used in packaging, automotive, construction, and healthcare. Circular models aim to preserve these benefits while reducing environmental impact.

Beyond environmental considerations, circularity can also support new business models. Companies involved in collection, sorting, and advanced recycling can create value by supplying recycled or waste-derived materials back into industrial production.

However, achieving higher levels of circularity requires technologies capable of handling complex and mixed plastic waste streams that are not easily managed through conventional recycling alone.

Supporting Plastic Circularity Through Advanced Recycling

Advanced recycling technologies are increasingly explored as part of a broader circular economy toolkit. These approaches focus on converting plastic waste into molecular-level outputs that can be reintroduced into industrial value chains.

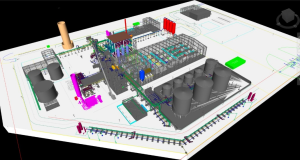

One such approach is the Thermal Conversion Process (TCP®), which is designed to process a broad range of carbon-containing waste streams, including hard-to-recycle plastics, into usable outputs.

Rather than replacing existing recycling methods, advanced recycling technologies can complement them by addressing waste fractions that are otherwise difficult to recycle and by supporting feedstock circularity at the molecular level.

Circular Naphtha Substitute and Industrial Compatibility

Within advanced recycling pathways, circular naphtha substitutes play a specific role. Naphtha-range molecules are widely used as feedstock in petrochemical production, particularly in steam cracking processes.

Circular naphtha substitutes are designed to deliver naphtha-range outputs derived from waste-based carbon, enabling compatibility with existing petrochemical infrastructure. Their value lies in continuity: supporting circularity while aligning with established industrial processes.

By reintroducing carbon already present in the system, circular naphtha substitutes can help reduce reliance on virgin fossil feedstocks without requiring fundamental changes to downstream assets.

Creating a Circular Economy Model

By converting waste plastics into feedstock molecules such as circular naphtha substitutes, advanced recycling technologies can support closed-loop material flows.

In this model, plastic waste is transformed into usable feedstock, processed into new materials, and ultimately returned to the value chain. This approach helps conserve resources, reduce waste generation, and support more circular material cycles.

Rather than positioning circularity as a single solution, this model illustrates how different recycling pathways can work together to improve overall system performance.

Circular Economy and Sustainability

A circular economy offers a framework for addressing plastic waste while supporting long-term sustainability goals. By improving material efficiency, reducing waste, and lowering dependence on virgin resources, circular approaches contribute to more resilient industrial systems.

Advanced recycling technologies and circular feedstocks are part of this evolving landscape. When integrated responsibly, they can help reduce environmental impact while maintaining the performance and availability of essential materials.

As industries continue to explore circular solutions, plastic recycling will remain a key area where innovation, infrastructure, and sustainability objectives intersect.